16ga. for turbo mani?

#1

Honda-Tech Member

Thread Starter

Join Date: Feb 2005

Location: PA

Posts: 375

Likes: 0

Received 0 Likes

on

0 Posts

Just as the title asks:

Is 16ga. strong enough to be used for a turbo manifold? This will be holding a relatively large turbo. I searched but couldn't find a straight answer. Thanks in advance--

Keith

Is 16ga. strong enough to be used for a turbo manifold? This will be holding a relatively large turbo. I searched but couldn't find a straight answer. Thanks in advance--

Keith

#3

For a turbo manifold I wouldn't work with anything less then schedule 10. Roughly .109 wall thickness on a 1.5" fitting. Easy math but 1/16 has a wall thickness of .0625

16ga has and will work...the manifolds I've seen in person made from 16ga do not hold up.

Modified by Keyhole at 9:36 AM 9/2/2005

16ga has and will work...the manifolds I've seen in person made from 16ga do not hold up.

Modified by Keyhole at 9:36 AM 9/2/2005

#4

Honda-Tech Member

Join Date: Jan 2003

Location: Charlotte, NC

Posts: 3,788

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Keyhole »</TD></TR><TR><TD CLASS="quote">For a turbo manifold I wouldn't work with anything less then schedule 10. Roughly .109 wall thickness on a 1.5" fitting. Easy math but 1/16 has a wall thickness of .0625

16ga has and will work...the manifolds I've seen in person made from 16ga do not hold up.

Modified by Keyhole at 9:36 AM 9/2/2005</TD></TR></TABLE>

More the likely they are not fabricated correctly and are requiring a thin piece of tubing thats constantly being heat cycled to hold a very large amount of weight.

16ga is probably more then adequate and will do what it's supposed to flow the exhaust gases to the turbo however it is not supposed to be used to support the weight of the turbo this is not the headers job

16ga has and will work...the manifolds I've seen in person made from 16ga do not hold up.

Modified by Keyhole at 9:36 AM 9/2/2005</TD></TR></TABLE>

More the likely they are not fabricated correctly and are requiring a thin piece of tubing thats constantly being heat cycled to hold a very large amount of weight.

16ga is probably more then adequate and will do what it's supposed to flow the exhaust gases to the turbo however it is not supposed to be used to support the weight of the turbo this is not the headers job

#5

i HAS questions ?

Join Date: Feb 2003

Location: OH

Posts: 7,850

Likes: 0

Received 0 Likes

on

0 Posts

Oh hell yes the great thin-walled tubing vs. plumbing pipe manifold thread is back again. Not to be a dick, but this comes up all the time. Half the people on here are going to say "you can run 16ga. tubing if you brace the turbo, which is the proper way to go." The other half are going to say "OMGWTFBBQ all my friends 16ga. manifolds cracked because it couldn't support the turbo. Make it out of 40 lbs of plumbing pipe thats the only way to go." So in the end its really your choice. The latter is less work in my opinion, which is why people tend to go that way.

#6

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Casey@Burns »</TD></TR><TR><TD CLASS="quote">More the likely they are not fabricated correctly and are requiring a thin piece of tubing thats constantly being heat cycled to hold a very large amount of weight.

16ga is probably more then adequate and will do what it's supposed to flow the exhaust gases to the turbo however it is not supposed to be used to support the weight of the turbo this is not the headers job</TD></TR></TABLE>

I would not disagree with any part of this...the people that made the manifolds I've seen/used had less than a good idea of what they were doing. Unfortunately even after supports were added there were still failures. I would have been interested to see the results had they made the same manifolds using sch40 or even sch10 fittings.

16ga is probably more then adequate and will do what it's supposed to flow the exhaust gases to the turbo however it is not supposed to be used to support the weight of the turbo this is not the headers job</TD></TR></TABLE>

I would not disagree with any part of this...the people that made the manifolds I've seen/used had less than a good idea of what they were doing. Unfortunately even after supports were added there were still failures. I would have been interested to see the results had they made the same manifolds using sch40 or even sch10 fittings.

#7

Honda-Tech Member

Thread Starter

Join Date: Feb 2005

Location: PA

Posts: 375

Likes: 0

Received 0 Likes

on

0 Posts

I thought 16ga. would be alittle too thin but I have heard of people using it, which is why I asked. I'll be using alot heavier gauge tubing for the peace of mind knowing it will hold the weight of the turbo without needing alot of bracing and whatnot.

Trending Topics

#8

Honda-Tech Member

Join Date: Jul 2004

Location: I'm everywhere Focker

Posts: 5,463

Likes: 0

Received 2 Likes

on

2 Posts

Has anyone found any of this useable 16ga tubing at places like Home Depot or anything? I need to make a couple manifolds and I need a source for the tubing (simple log style or simple runner manifolds). I have fabricated surge tanks, intercoolers and other things, but have yet to make manifolds.

Any help is appreciated.

Any help is appreciated.

#9

OG Fabricator

Join Date: Mar 2003

Location: Knoxville, tn, 37912

Posts: 1,438

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by daveG »</TD></TR><TR><TD CLASS="quote"> [using pipe] is less work in my opinion, which is why people tend to go that way.</TD></TR></TABLE>

Personally, I'd rather work with tubing. You don't need to bevel it or weld in multiple passes. It grinds and cuts faster also.

Personally, I'd rather work with tubing. You don't need to bevel it or weld in multiple passes. It grinds and cuts faster also.

#10

Honda-Tech Member

Join Date: Jan 2003

Location: Charlotte, NC

Posts: 3,788

Likes: 0

Received 0 Likes

on

0 Posts

I<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by RC000E »</TD></TR><TR><TD CLASS="quote">Has anyone found any of this useable 16ga tubing at places like Home Depot or anything? I need to make a couple manifolds and I need a source for the tubing (simple log style or simple runner manifolds). I have fabricated surge tanks, intercoolers and other things, but have yet to make manifolds.

Any help is appreciated. </TD></TR></TABLE>

</TD></TR></TABLE>

I don't think Home Depot has what your looking for but i'm sure we do if your looking for stainless that is. http://www.burnsstainless.com

Any help is appreciated.

</TD></TR></TABLE>

</TD></TR></TABLE>I don't think Home Depot has what your looking for but i'm sure we do if your looking for stainless that is. http://www.burnsstainless.com

#11

i HAS questions ?

Join Date: Feb 2003

Location: OH

Posts: 7,850

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Engloid »</TD></TR><TR><TD CLASS="quote">Personally, I'd rather work with tubing. You don't need to bevel it or weld in multiple passes. It grinds and cuts faster also.</TD></TR></TABLE>

Not everybody is a welding god like you though.

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Casey@Burns »</TD></TR><TR><TD CLASS="quote">I

I don't think Home Depot has what your looking for but i'm sure we do if your looking for stainless that is. http://www.burnsstainless.com</TD></TR></TABLE>

All I've seen at Home Depot is conduit. Unless you want to make a copper exhaust manifold.

Not everybody is a welding god like you though.

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Casey@Burns »</TD></TR><TR><TD CLASS="quote">I

I don't think Home Depot has what your looking for but i'm sure we do if your looking for stainless that is. http://www.burnsstainless.com</TD></TR></TABLE>

All I've seen at Home Depot is conduit. Unless you want to make a copper exhaust manifold.

#12

Honda-Tech Member

Join Date: Jul 2004

Location: I'm everywhere Focker

Posts: 5,463

Likes: 0

Received 2 Likes

on

2 Posts

Well, I have only TIG'd mild steel and aluminum, never stainless yet. I assume though if I can weld mild and aluminum I should be fine. I was just thinking in terms of keeping costs down to make some simple turbo manifolds for the locals.

What thickness of stainless is generally acceptable for a streetable turbo manifold that is simple in design as well?

What thickness of stainless is generally acceptable for a streetable turbo manifold that is simple in design as well?

#13

i HAS questions ?

Join Date: Feb 2003

Location: OH

Posts: 7,850

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by RC000E »</TD></TR><TR><TD CLASS="quote">Well, I have only TIG'd mild steel and aluminum, never stainless yet. I assume though if I can weld mild and aluminum I should be fine. I was just thinking in terms of keeping costs down to make some simple turbo manifolds for the locals.

What thickness of stainless is generally acceptable for a streetable turbo manifold that is simple in design as well?</TD></TR></TABLE>

A lot of people use Sch.40 bends if you don't want to have to brace them.

What thickness of stainless is generally acceptable for a streetable turbo manifold that is simple in design as well?</TD></TR></TABLE>

A lot of people use Sch.40 bends if you don't want to have to brace them.

#14

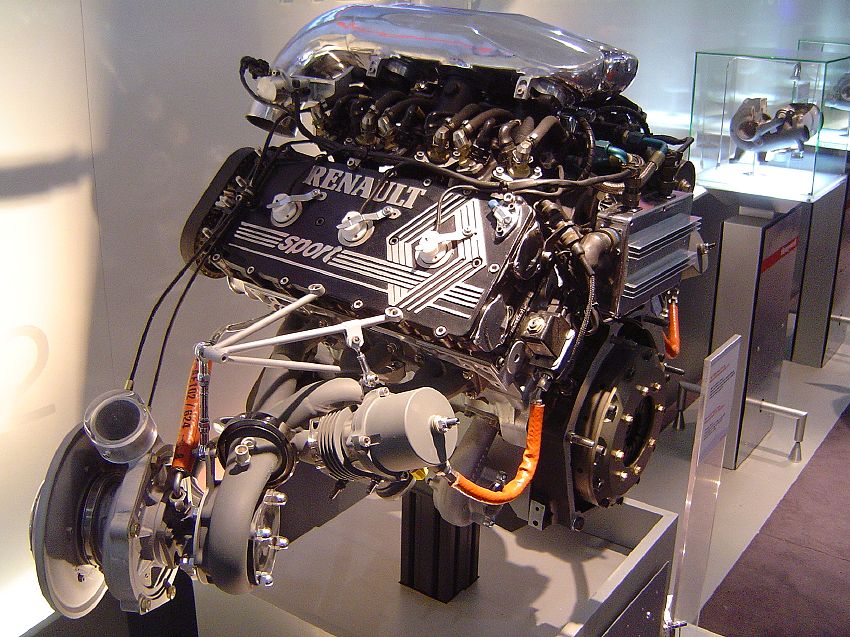

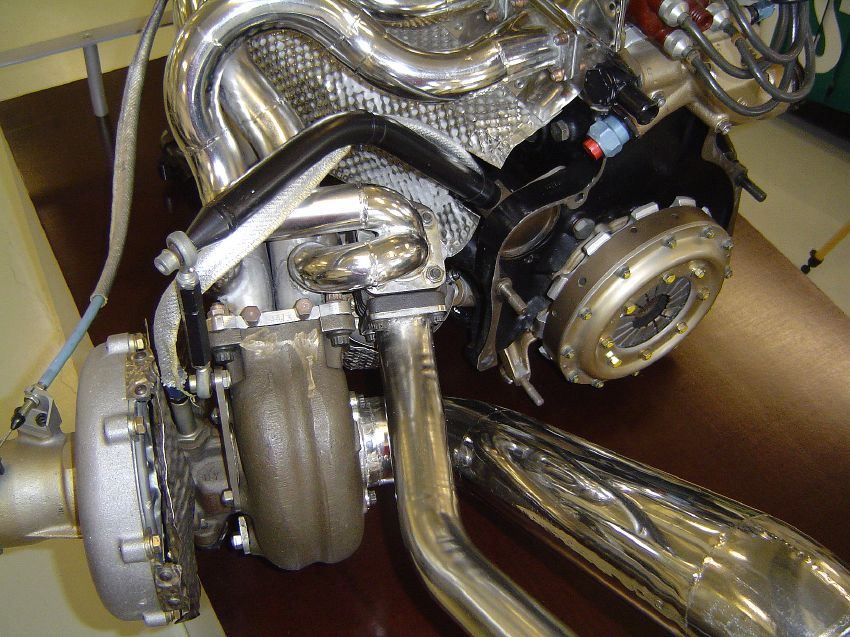

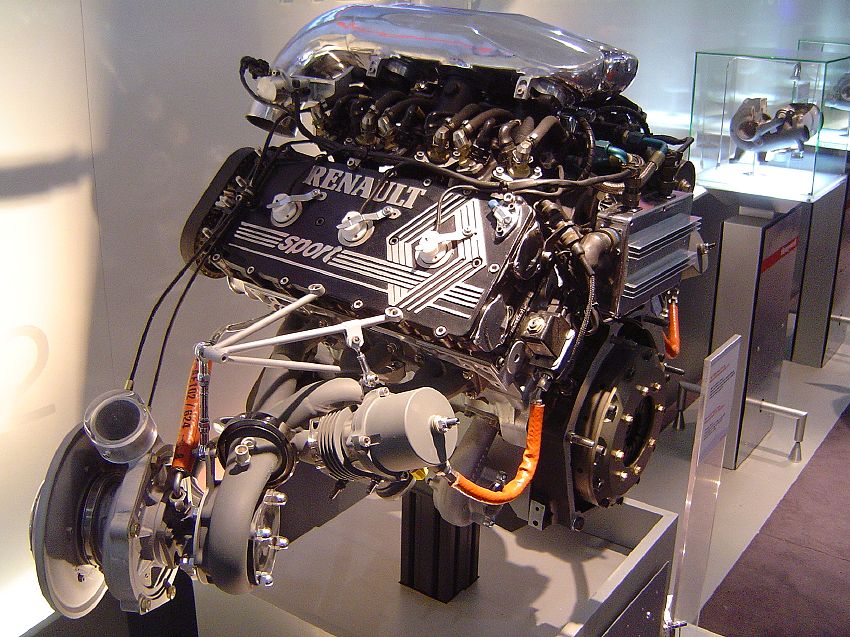

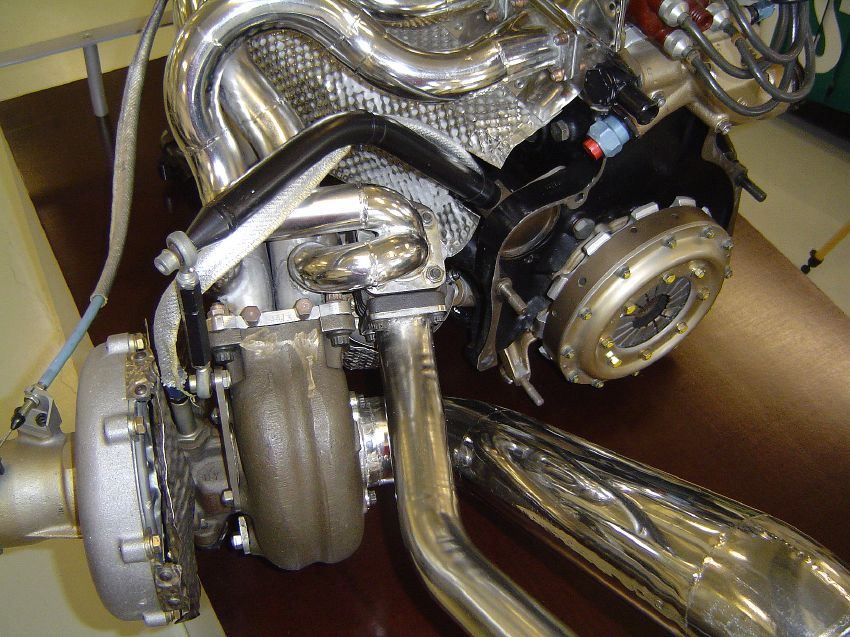

Properly braced 16ga will work fine. Using a brace similar to this:

The heim joint setup allows the manifold to move the turbo around as the material expands when it gets hot, but still supports the weight of the turbo. Notice the brace on the wastegate as well on the first picture.

Modified by civicross at 10:30 AM 9/13/2005

The heim joint setup allows the manifold to move the turbo around as the material expands when it gets hot, but still supports the weight of the turbo. Notice the brace on the wastegate as well on the first picture.

Modified by civicross at 10:30 AM 9/13/2005

#16

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by daveG »</TD></TR><TR><TD CLASS="quote">A lot of people use Sch.40 bends if you don't want to have to brace them.</TD></TR></TABLE>

Is there any downsides to using sch. 40? Is there a "thresh hold" , if you will, of weight that an exhaust flange can support? The whole bracing thing to me makes since to me regardless of if you use sch. 40 or not, but maybe im wrong? What things can go wrong if you use sch. 40 with out supporting the setup? I know that theres pros and cons to this....maybe someone can enlighten me.

Is there any downsides to using sch. 40? Is there a "thresh hold" , if you will, of weight that an exhaust flange can support? The whole bracing thing to me makes since to me regardless of if you use sch. 40 or not, but maybe im wrong? What things can go wrong if you use sch. 40 with out supporting the setup? I know that theres pros and cons to this....maybe someone can enlighten me.

#17

i HAS questions ?

Join Date: Feb 2003

Location: OH

Posts: 7,850

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by InfamousDC2FI »</TD></TR><TR><TD CLASS="quote">Is there any downsides to using sch. 40? Is there a "thresh hold" , if you will, of weight that an exhaust flange can support? The whole bracing thing to me makes since to me regardless of if you use sch. 40 or not, but maybe im wrong? What things can go wrong if you use sch. 40 with out supporting the setup? I know that theres pros and cons to this....maybe someone can enlighten me.  </TD></TR></TABLE>

</TD></TR></TABLE>

You could brace a sch. 40 manifold, but it'd more than likely be overkill as its been shown that they can support the weight of a turbo.

</TD></TR></TABLE>

</TD></TR></TABLE>You could brace a sch. 40 manifold, but it'd more than likely be overkill as its been shown that they can support the weight of a turbo.

Thread

Thread Starter

Forum

Replies

Last Post

90civichbsi

Forced Induction

14

07-22-2005 10:57 PM