THE OFFICIAL compression height and center to center calculations thread

#1

Thread Starter

There are always posts in which people ask for help with rod center to center length or compression height calculations. It seems its always the same few members doing the calculations for the rest. There is no secret or near impossible task involved with these calculations, its really just simple elementary school math. The only thing that may seem a little discouraging may be the actual formulas involved in the calculations themselves.

With the recent addition of the Offset Grind I figured there would be a lot of people asking what compression height or center to center rod lengths they will need with any given combination. But first, for those who are unfamiliar with the terms compression height and center to center Im going to take some time to describe each of the two.

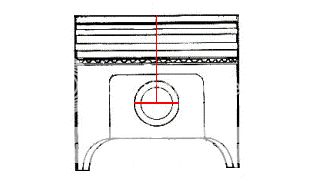

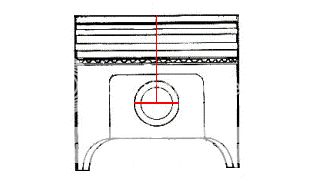

What is compression height?

Compression height is the measurement from the pin bore centerline to the deck of the piston. It is essentially the height of the piston.

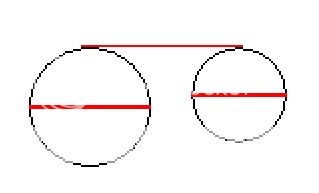

Here is an example:

Compression height changes are required when you increase the rod and crankshafts total height at top dead center. This can occur by increasing center to center length of the rod, by increasing stroke or, through a combination of both increased center to center length and increased stroke. You will then need to shorten the compression height to accommodate for the additional total height of the stroke and center to center length of the rod at TDC. you do this by moving the wrist pin location further up into the piston. This will change the centerline of the wrist pin and in turn, give you a shorter compression height.

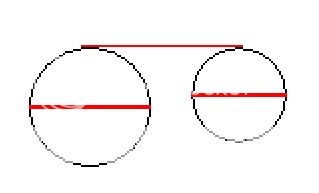

There are limitations as to how short you can go with the compression height of a piston. For that, your going to have to factor in the diameter of the wrist pin you are using as well as the ring pack being used on the piston itself. Generally, you want to try and avoid pushing the wrist pin, or pin bore into the oil ring grove. You run the risk of additional oil consumption by doing so which in some cases, may not be too bad. But than again, there are other occasions in which oil consumption can be as high as 1 quart every 200 miles. You can run a smaller pin diameter to give yourself a little more room to work with. The smaller pin will allow you to go a bit shorter or, higher into the piston. The reason is simple, a smaller diameter pin will have a higher centerline than a larger diameter pin will when positioned at the same point.

Here is an illustration to give you an example:

That pretty much covers compression heights for streetable applications.

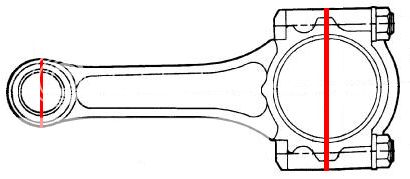

What is the center to center measurement of the rod?

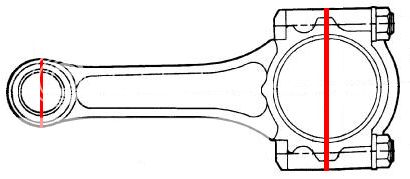

Center to center is a term used to describe the measurement from the centerline of the BE bore to the centerline of the pin bore of any given connecting rod. Hence the term "center to center."

Illustration of the center points of measurement:

Pretty simple, nothing that really needs to be explained in detail.

How do I calculate the compression height and or rod length I will need?

The formulas are fairly simple and are as follows:

<FONT COLOR="red">Formula for calculating compression height</FONT>

Block Height - Stroke in inches/2 - Center to center - Desired deck clearance = Compression height

<FONT COLOR="red">Formula for calculating the center to center length of the rod</FONT>

Block Height - Stroke in inches/2 - Compression height - Desired deck clearance = Center to center

<FONT COLOR="red">Formula for calculating deck clearance</FONT>

Block Height - Stroke in inches/2 - Compression height - Center to center = Deck clearance

<FONT COLOR="red">Formula for converting mm to inches</FONT>

Xmm/25.4 = stroke in inches

For the calculation of compression height, center to center length or deck clearance you must divide the stroke in inches by 2.

<FONT COLOR="blue">example</FONT>

stroke in inches/2

For most specs needed for calculations you can check out The official H/F piston/rod/crank/block specs and CR thread

Hope this can be of help to some of you guys...

More to come

With the recent addition of the Offset Grind I figured there would be a lot of people asking what compression height or center to center rod lengths they will need with any given combination. But first, for those who are unfamiliar with the terms compression height and center to center Im going to take some time to describe each of the two.

What is compression height?

Compression height is the measurement from the pin bore centerline to the deck of the piston. It is essentially the height of the piston.

Here is an example:

Compression height changes are required when you increase the rod and crankshafts total height at top dead center. This can occur by increasing center to center length of the rod, by increasing stroke or, through a combination of both increased center to center length and increased stroke. You will then need to shorten the compression height to accommodate for the additional total height of the stroke and center to center length of the rod at TDC. you do this by moving the wrist pin location further up into the piston. This will change the centerline of the wrist pin and in turn, give you a shorter compression height.

There are limitations as to how short you can go with the compression height of a piston. For that, your going to have to factor in the diameter of the wrist pin you are using as well as the ring pack being used on the piston itself. Generally, you want to try and avoid pushing the wrist pin, or pin bore into the oil ring grove. You run the risk of additional oil consumption by doing so which in some cases, may not be too bad. But than again, there are other occasions in which oil consumption can be as high as 1 quart every 200 miles. You can run a smaller pin diameter to give yourself a little more room to work with. The smaller pin will allow you to go a bit shorter or, higher into the piston. The reason is simple, a smaller diameter pin will have a higher centerline than a larger diameter pin will when positioned at the same point.

Here is an illustration to give you an example:

That pretty much covers compression heights for streetable applications.

What is the center to center measurement of the rod?

Center to center is a term used to describe the measurement from the centerline of the BE bore to the centerline of the pin bore of any given connecting rod. Hence the term "center to center."

Illustration of the center points of measurement:

Pretty simple, nothing that really needs to be explained in detail.

How do I calculate the compression height and or rod length I will need?

The formulas are fairly simple and are as follows:

<FONT COLOR="red">Formula for calculating compression height</FONT>

Block Height - Stroke in inches/2 - Center to center - Desired deck clearance = Compression height

<FONT COLOR="red">Formula for calculating the center to center length of the rod</FONT>

Block Height - Stroke in inches/2 - Compression height - Desired deck clearance = Center to center

<FONT COLOR="red">Formula for calculating deck clearance</FONT>

Block Height - Stroke in inches/2 - Compression height - Center to center = Deck clearance

<FONT COLOR="red">Formula for converting mm to inches</FONT>

Xmm/25.4 = stroke in inches

For the calculation of compression height, center to center length or deck clearance you must divide the stroke in inches by 2.

<FONT COLOR="blue">example</FONT>

stroke in inches/2

For most specs needed for calculations you can check out The official H/F piston/rod/crank/block specs and CR thread

Hope this can be of help to some of you guys...

More to come

#2

How small of a compression height can you generally go with a custom H/F piston? I assume it would be determined by the diameter of the wrist pin, but how much extra material would you need above that?

Modified by Sam1am26 at 9:17 PM 7/27/2005

Modified by Sam1am26 at 9:17 PM 7/27/2005

#4

moderator emeritus

i wish rick was still around  , prime example of a brilliant man.

, prime example of a brilliant man.

, prime example of a brilliant man.

, prime example of a brilliant man.

Thread

Thread Starter

Forum

Replies

Last Post