How It’s Made: Honda Civic Type R

Honda’s flagship performance car is not a one-trick pony thanks to a solid foundation.

It is not uncommon for automotive manufacturers to dig into their own parts bin. This usually causes models such as the Honda Civic to look fairly similar between its base model and flagship, the Type R. At first, obvious details will catch the eye: minor adjustments to light shapes, bumper styling, and color options. Underneath the aesthetics are actually where the differences become major. The distinguishing details between a “normal” Civic and its top tier model are often unnoticeable to the untrained eye, leading some to believe that it’s merely a “souped up” version of the same car.

Japanese auto manufacturer Toyota developed a philosophy of “reduction of movement/waste” and “small incremental changes lead to large improvements” that is better known as the Toyota Production System or Lean Manufacturing. This concept does not apply only to just production environments, but also heavily in design. It’s very common to see models available on the dealership floors that look somewhat similar, but with hefty price tag differences due to a laundry list of differences between them.

When comparing the spec sheets of Sport Touring trim to the Type R, it becomes obvious that there are major differences between the two. The Sport Touring is based on a standard Civic 5-door hatchback design. This means it has smaller sized wheels, a lower heat capacity radiator, and different front facia design that focuses on aesthetics over performance. The design intent of the “regular” Civic was to create a comfortable and efficient road going car that can fulfill all the needs a daily driver would ask for.

But, when placed next to an FL5 Civic Type R, the differences go beyond aesthetic and quickly become noticeable that although they share the same body style, it is in fact a street-legal turn-key race ready vehicle. The Civic Type R starts life as a standard Civic hatchback, but gets increased chassis stiffness thanks to additional supports throughout the body in critical areas. The larger displacement engine, brakes, wheels/tires, and even interior pieces focus on performance and survival during harsh driving environments such as the Nurburgring. Because it is based on the standard Civic chassis, the FL5 not only is an enthusiast focused performance car, but it can also be comfortably utilized in regular everyday conditions. The small increment improvement process as taught by Toyota, has allowed the Type R to be a Swiss-Army knife, ready to do whatever task needed.

Details such as the front fascia features an aerodynamically improved shape, unique mesh grill, and a larger opening to feed large amounts of cool air directly to the radiator. This was a major need from the previous generation FK8 Civic Type R that was plagued with cooling issues due to the bumper design. Forged wheels wrapped with sticky Michelin tires, a 5×120 lug pattern, larger diameter wheel studs, and performance brakes are just the obvious details when it comes to the suspension. Deeper inside, a performance oriented shock and spring combination with additional “R+” drive mode all add to the feature list that further distinguishes it from being just aesthetically different from its counterpart.

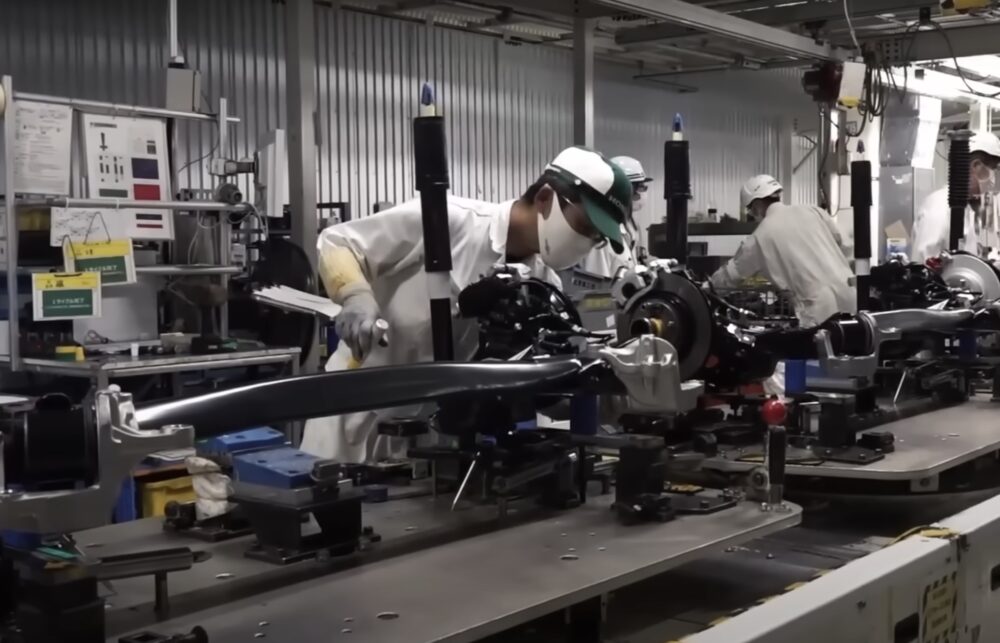

Life for both trim levels start the same, with flat stock sheet metal in both aluminum and steel are laser cut, sorted, and formed into components that will later be welded or bonded together to create the foundation. After this fully automated process, the complete shell then proceeds onto paint, a manual visual inspection is completed, and if all goes well it goes onto the final assembly stage. This is where multiple sub-assemblies such as the front and rear suspension are bolted to the chassis after being assembled off the line.

The engine of the FL5 CTR bares similarity to its previous “Type R” counterparts by being carefully hand assembled prior to finding its final resting place in the engine bay. This human touch is present throughout the assembly process as automated processes cannot always replicate the level of detail required. Once fully assembled, the car is subject to a digital wheel alignment, engine output verification, and it is ready to hit the track, or the street.

To bring the Civic or any vehicle to the next level of performance will require a human touch. While Honda has developed a strong all-around performance car, it’s fellow Japanese brand Toyota has also released their own version of a well-rounded hot-hatch, known as the Toyota GR Corolla. It shares the same ideology, with building from a base Corolla hatchback but with the addition of an AWD platform, turbocharged engine, and expectation that these may become full blown race cars in the right hands.

Toyota’s “Gazoo Racing” motorsport division takes the Corolla in and does exactly just that. In order to make it a full blown race car, a hands-on assembly process replaces the robots. An example of this is fitting the roll cage in, where each individual tube is cut, bent, and welded in on a need-by basis. The specific locations and style of bends largely depends on the type of racing the car will be competing in and even the size of the driver.

One could argue that converting the road going car is technically lean principles in practice – with literally stripping away things that aren’t needed along with changing details to accommodate new requirements like larger tires, additional suspension travel, and extremely harsh environments to function in. To those who still refuse to acknowledge, regardless of what you do, it’ll still be a ‘normal’ Corolla or Civic. But, we now know there’s much more to these cars than just a different badge.