Recent exhaust work

#426

OG Fabricator

Thread Starter

Join Date: Dec 2006

Location: Calgary, Alberta, Canada

Posts: 1,342

Likes: 0

Received 0 Likes

on

0 Posts

Yeah, we have 2 possible return fittings beside the pick-up tube. He talked with a few companies and they expressed concerns with the heat of the returned fuel too close to the pick-up.

The tube going through can't be avoided. Certain lines have to pass through. There will be clamps on both sides to hold the lines, and a rubber surface placed on the ID. We just made the hole double the size of the original and round instead of square.

The tube going through can't be avoided. Certain lines have to pass through. There will be clamps on both sides to hold the lines, and a rubber surface placed on the ID. We just made the hole double the size of the original and round instead of square.

#427

Honda-Tech Member

Join Date: Aug 2008

Location: Oklahoma City, OK, USA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

Once again excellent welding, always a pleasure to see.

I have some 16g 304L tubing i need to weld, but ive been practicing lately and im learning quick now that using 1/16 filler rod isnt fun to weld with, so now i am trying to source out some .045 diameter filler rod. However the local welding stores wont be open again until tuesday and not even sure if they carry that kind. My question is are you purchasing your smaller diameter rods locally where you are or are you having to order them online? You dont have to name the place you get from, Im just wondering since i dont know if the stores where i am will have or not.

I have some 16g 304L tubing i need to weld, but ive been practicing lately and im learning quick now that using 1/16 filler rod isnt fun to weld with, so now i am trying to source out some .045 diameter filler rod. However the local welding stores wont be open again until tuesday and not even sure if they carry that kind. My question is are you purchasing your smaller diameter rods locally where you are or are you having to order them online? You dont have to name the place you get from, Im just wondering since i dont know if the stores where i am will have or not.

#428

OG Fabricator

Thread Starter

Join Date: Dec 2006

Location: Calgary, Alberta, Canada

Posts: 1,342

Likes: 0

Received 0 Likes

on

0 Posts

Once again excellent welding, always a pleasure to see.

I have some 16g 304L tubing i need to weld, but ive been practicing lately and im learning quick now that using 1/16 filler rod isnt fun to weld with, so now i am trying to source out some .045 diameter filler rod. However the local welding stores wont be open again until tuesday and not even sure if they carry that kind. My question is are you purchasing your smaller diameter rods locally where you are or are you having to order them online? You dont have to name the place you get from, Im just wondering since i dont know if the stores where i am will have or not.

I have some 16g 304L tubing i need to weld, but ive been practicing lately and im learning quick now that using 1/16 filler rod isnt fun to weld with, so now i am trying to source out some .045 diameter filler rod. However the local welding stores wont be open again until tuesday and not even sure if they carry that kind. My question is are you purchasing your smaller diameter rods locally where you are or are you having to order them online? You dont have to name the place you get from, Im just wondering since i dont know if the stores where i am will have or not.

I get all my rod from Universal Wire Works, Houston, Texas. Bruce is the best damn customer service guy I've dealt with. He is also very knowledgeable in all things wire.

I ship welding wire 2200 miles. That says it all. Tell him Chris sent you, he gets a kick out of us Canadians! I usually order with a co-worker who repairs boat props. Split the shipping etc.

#429

Honda-Tech Member

Join Date: Aug 2008

Location: Oklahoma City, OK, USA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the reply,

Im going to wait until the stores open up again and check there first. I dont need very much, just a pound at most and not sure what the minimum pound the place you get from is to order. Ive notice that most places is a minimum of 10lb online, which is way to much for someone like me. HEHE, when i do call them, ill let them know chris sent me and see what they say.

Im going to wait until the stores open up again and check there first. I dont need very much, just a pound at most and not sure what the minimum pound the place you get from is to order. Ive notice that most places is a minimum of 10lb online, which is way to much for someone like me. HEHE, when i do call them, ill let them know chris sent me and see what they say.

#430

Thanks for the reply,

Im going to wait until the stores open up again and check there first. I dont need very much, just a pound at most and not sure what the minimum pound the place you get from is to order. Ive notice that most places is a minimum of 10lb online, which is way to much for someone like me. HEHE, when i do call them, ill let them know chris sent me and see what they say.

Im going to wait until the stores open up again and check there first. I dont need very much, just a pound at most and not sure what the minimum pound the place you get from is to order. Ive notice that most places is a minimum of 10lb online, which is way to much for someone like me. HEHE, when i do call them, ill let them know chris sent me and see what they say.

maybe try looking for a spool of mig wire like the 2lbs spools then just cut what you need and straighten it

like this

http://cgi.ebay.com/ER308L-Stainless...item335a066bc2

#431

Honda-Tech Member

The tank looks great!

Do you sheer all your own aluminum? I get some steller pricing on laser and waterjet cutting locally so if you need anything CAD'd up and cut let me know. Also got a new machinist working with us and his hourly rate is 2nd to none.

Do you sheer all your own aluminum? I get some steller pricing on laser and waterjet cutting locally so if you need anything CAD'd up and cut let me know. Also got a new machinist working with us and his hourly rate is 2nd to none.

#432

OG Fabricator

Thread Starter

Join Date: Dec 2006

Location: Calgary, Alberta, Canada

Posts: 1,342

Likes: 0

Received 0 Likes

on

0 Posts

Used to use a circular saw with a straight edge to cut the grooves in our step forms for the concrete companies. Worked great.

The shipping would make it hard, but I might look into it locally if I do more tanks.

#433

Honda-Tech Member

Actually, cut it with a circular saw!!! Works great. Table saw would be even better, but my hands are pretty steady with a straight-edge!

Used to use a circular saw with a straight edge to cut the grooves in our step forms for the concrete companies. Worked great.

The shipping would make it hard, but I might look into it locally if I do more tanks.

Used to use a circular saw with a straight edge to cut the grooves in our step forms for the concrete companies. Worked great.

The shipping would make it hard, but I might look into it locally if I do more tanks.

I'm too lazy, anything I can I get cut. The nesting software actually makes it cheaper then buying a fullsheet and plasma cutting things out of it.

Sometimes shipping's not too bad if you throw it on the old greyhound.

#434

Honda-Tech Member

Join Date: Aug 2008

Location: Oklahoma City, OK, USA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

maybe try looking for a spool of mig wire like the 2lbs spools then just cut what you need and straighten it

like this

http://cgi.ebay.com/ER308L-Stainless...item335a066bc2

like this

http://cgi.ebay.com/ER308L-Stainless...item335a066bc2

#435

OG Fabricator

Join Date: Mar 2003

Location: Columbus, Ohio, USA

Posts: 513

Likes: 0

Received 0 Likes

on

0 Posts

What kind of blade do you use on the circular saw? I have found myself doing many misc tanks whether huge coolant reservoirs to fuel cells, its quite the hassle to take everything to a shop to shear or cut with the angle grinder and an alum wheel.

#436

OG Fabricator

Thread Starter

Join Date: Dec 2006

Location: Calgary, Alberta, Canada

Posts: 1,342

Likes: 0

Received 0 Likes

on

0 Posts

Finishing blade. More teeth.

#437

Honda-Tech Member

Join Date: Sep 2006

Location: Mid-Michigan, USA

Posts: 1,235

Likes: 0

Received 0 Likes

on

0 Posts

I cut the runners off of a factory intake manifold with a circular saw last year... lol

Circular saws definitely fly through aluminum.

Circular saws definitely fly through aluminum.

#438

OG Fabricator

Thread Starter

Join Date: Dec 2006

Location: Calgary, Alberta, Canada

Posts: 1,342

Likes: 0

Received 0 Likes

on

0 Posts

Alright, haven't been doing much for various reasons. Here are the latest little projects...

Dyno anchors for buddy's new shop. We saved 5ft of wasted space behind the dyno by using anchors to maintain the same angle. I even threw on a few extras because you never know.

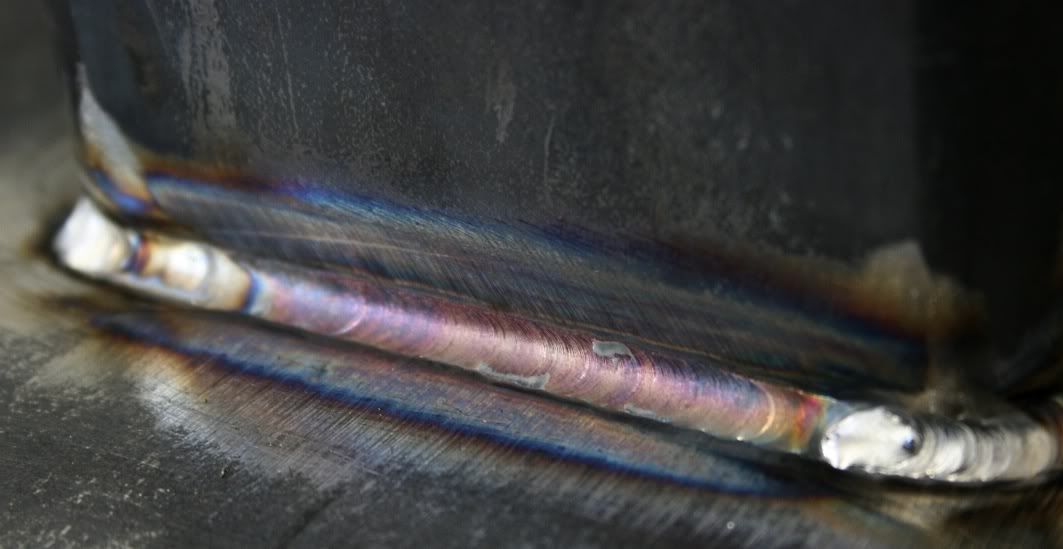

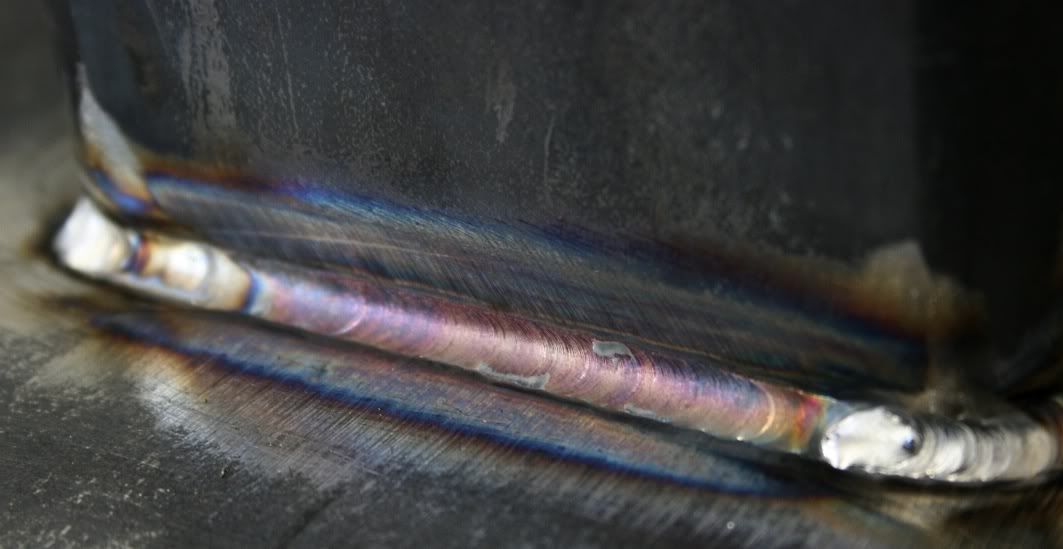

Root pass on the d-ring brackets. Not sure why I didn't take cap pics, they turned out great..

Root pass on tube to plate joints.

Modifying that crazy subaru header to a single WG, he's putting the whole kit in a newer white car, and going with another crazy set-up in the blue car. This was a little tricky with the room spec'd by the customer, but turned out ok. I didn't clean it up as it was going for coating right after I was done.

So, from the dual WG set-up here...

To block off one, make another hole, and join to the other...

Then, after that, a much needed break with the fam...

Dyno anchors for buddy's new shop. We saved 5ft of wasted space behind the dyno by using anchors to maintain the same angle. I even threw on a few extras because you never know.

Root pass on the d-ring brackets. Not sure why I didn't take cap pics, they turned out great..

Root pass on tube to plate joints.

Modifying that crazy subaru header to a single WG, he's putting the whole kit in a newer white car, and going with another crazy set-up in the blue car. This was a little tricky with the room spec'd by the customer, but turned out ok. I didn't clean it up as it was going for coating right after I was done.

So, from the dual WG set-up here...

To block off one, make another hole, and join to the other...

Then, after that, a much needed break with the fam...

#441

OG Fabricator

Thread Starter

Join Date: Dec 2006

Location: Calgary, Alberta, Canada

Posts: 1,342

Likes: 0

Received 0 Likes

on

0 Posts

Thanks. The dyno anchors could have been welded by my daughter and the guy would not have cared. I painted it Ford Blue, that is all that matters.

This is the same guy that has multiple 500whp stangs, all of which I've worked on, and the race car has 520whp n/a, runs 9.40's at 140mph.

This is the same guy that has multiple 500whp stangs, all of which I've worked on, and the race car has 520whp n/a, runs 9.40's at 140mph.

#443

OG Fabricator

Thread Starter

Join Date: Dec 2006

Location: Calgary, Alberta, Canada

Posts: 1,342

Likes: 0

Received 0 Likes

on

0 Posts

#446

OG Fabricator

Thread Starter

Join Date: Dec 2006

Location: Calgary, Alberta, Canada

Posts: 1,342

Likes: 0

Received 0 Likes

on

0 Posts

Thanks boys.

Here is some of the latest goings-on around my little garage...

Oil pan mod to remove front sump. Install will be much easier. Also hacked off both sump drain plugs, as the access plugs can be used. All to save space. This will be getting some very custom headers in the summer...

Here is the inside, penetration is all the way through, no leaking.

More Ford stuff...

X-pipe for GT500 exhaust system.

Colours are a little whack on this pic, not sure why.(not a pro photog, for sure!)

Here is some of the latest goings-on around my little garage...

Oil pan mod to remove front sump. Install will be much easier. Also hacked off both sump drain plugs, as the access plugs can be used. All to save space. This will be getting some very custom headers in the summer...

Here is the inside, penetration is all the way through, no leaking.

More Ford stuff...

X-pipe for GT500 exhaust system.

Colours are a little whack on this pic, not sure why.(not a pro photog, for sure!)

#447

Honda-Tech Member

Join Date: Oct 2009

Location: Griffin Ga

Posts: 1,420

Likes: 0

Received 0 Likes

on

0 Posts

Yes, the fuel cell was tested with air and soapy water on all seams and fittings. This is how I tested oil storage tanks in industry for years. Works great, just have to be careful. I need to get a gauge though. Right now I carefully add air until the largest flat surface moves slightly.

This is the biggest reason I place large stitches inside the fuel cells when I build them. We used to test the oil tanks at 2lbs, pretty sure my method is more. Please, if anybody tries to do this without a gauge like me, have almost no pressure in your compressor/tank. 10-15 lbs max.

It would be hard to test the fuel lines, so he is going to test it for me with a blind fitting and pressure up the system. I have no reason to believe it would leak. It welded just fine.

This is the biggest reason I place large stitches inside the fuel cells when I build them. We used to test the oil tanks at 2lbs, pretty sure my method is more. Please, if anybody tries to do this without a gauge like me, have almost no pressure in your compressor/tank. 10-15 lbs max.

It would be hard to test the fuel lines, so he is going to test it for me with a blind fitting and pressure up the system. I have no reason to believe it would leak. It welded just fine.

#449

Honda-Tech Member

This is the same way we test hydraulic cylinders. we test to 100 psi, utilize a weld around and a weld lathe. the welds are not quite as pretty, but they work fine for some of our clients. we were testing using just a fitting and pulsing it as you are. we purchased a tire gauge from snap on and it works fine.

I test mine to 3000PSI....

Shizzit looks good bells!

#450

Honda-Tech Member

Join Date: Oct 2009

Location: Griffin Ga

Posts: 1,420

Likes: 0

Received 0 Likes

on

0 Posts

just looking for bubbles, thats it...

but thats with air. we only need to test hydraulically when we are doing repairs.

as for the welder, i think its a waste.

but thats with air. we only need to test hydraulically when we are doing repairs.

as for the welder, i think its a waste.